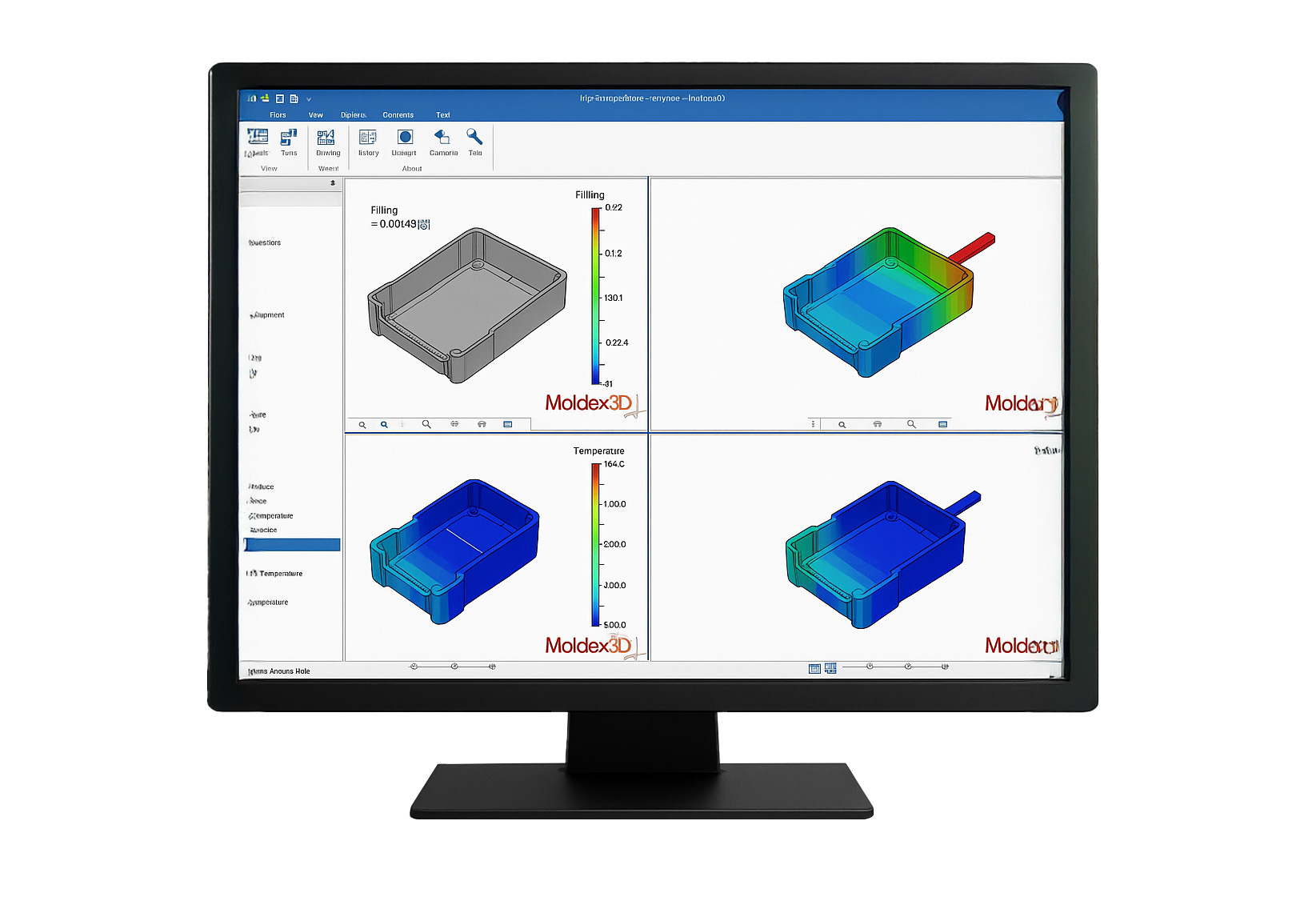

Mold Flow Analysis

Supporting customers in product design and improving production efficiency.

Mold flow analysis simulates the plastic injection molding process before mass production.

This ensures consistent quality, shortens development cycles, and save mold trial costs, making it crucial to high quality plastic product manufacturing.

Mold Flow Analysis

Identify potential defects such as air traps, weld lines, and sink marks.

Holding Pressure Analysis

Evaluate pressure distribution during the packing stage to improve molding stability and reduce sink marks or deformation.

Warp Analysis

Simulates deformation after cooling to identify warpage causes and optimize the design.

Cooling Analysis

Predicts the efficiency of the cooling system to ensure uniform cooling and prevent warpage or deformation.

Defect Prediction

Proactively predict defects such as weld lines, bubbles, jetting marks, and short shots.

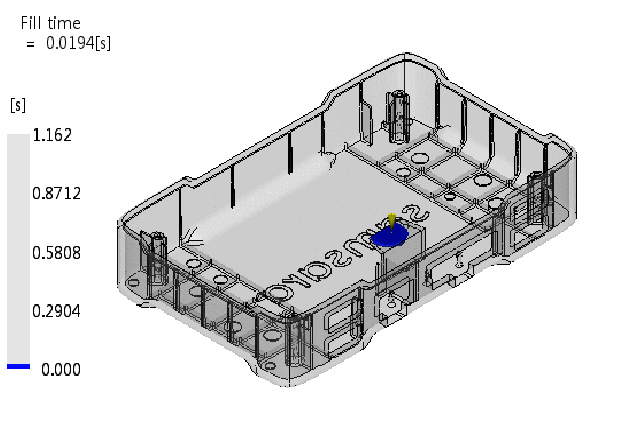

Mold Flow Analysis(Advanced)

T0

Pre-mold Analysis

Perform real mold testing on injection machines using parameters from simulations.

T1

Generating Real Data

The equipment outputs real values for key parameters like injection pressure, temperature, and cooling time.

T2-Tf

Precision Optimization

Modifying the mold design and reruning simulation improve accuracy.