Chung Hua Plastic integrates advanced testing equipment covering dimensional measurement, material analysis, environmental simulation, impact resistance, and sealing performance. With smart factory automation and data monitoring, we ensure every process meets international quality standards, delivering reliable and secure results to our clients.

3D Coordinate Measuring Machine (CMM)

Using high-precision probes and optical scanning to quickly capture X/Y/Z dimensions and geometry, ideal for inspecting geometric tolerances of plastic parts.

Automatic Vision Measuring System

Uses image recognition for automatic measurement of length, width, hole size, and spacing—fast and highly repeatable, ideal for high-volume inspections.

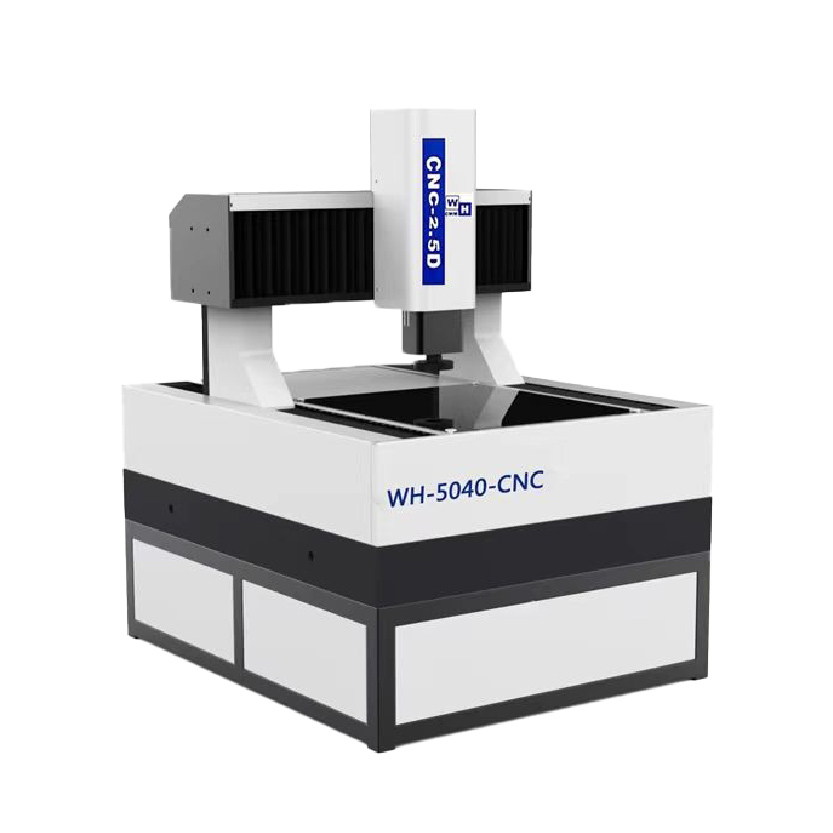

2.5D Vision Measuring System

Combines imaging and height scanning to measure flatness and slight height variations—ideal for surface structures and small component analysis.

Energy Dispersive X-ray Fluorescence Spectrometer

Non-destructive elemental analysis to quickly detect RoHS-restricted substances (e.g., lead, cadmium) in metal or plastic materials.

Color Difference Meter

Measures surface color accuracy to verify compliance with color standards—commonly used for appearance quality control and color consistency checks.

Thermal Shock Tester

Simulates extreme temperature fluctuations to test product stability and crack resistance under thermal stress.

Temperature and Humidity Test Chamber

Simulates storage and operation under varying temperature and humidity to check for deformation, aging, or deterioration.

Boiling Test Machine

Uses boiling water tests to verify sealing and material durability under high heat and humidity—commonly applied for waterproof testing of plastic components.

Force Gauge

Tests product strength and failure points under tension or compression—commonly used to assess the durability of joints, hinges, or fasteners.

Ball Drop Impact Tester

Drops a steel ball from a fixed height to check for cracks or deformation—evaluates impact resistance.

Melt Flow Index Tester

Measures the flowability of thermoplastics under heat and load—higher values indicate easier flow, used for material grade control.

RCA Abrasion Tester

Uses standardized pressure and abrasive rotation to test coating wear resistance—commonly applied to plating, painting, or printed films.

Water Leak Tester

Places the product in pressurized water to check for bubbles, a common method for waterproof testing.

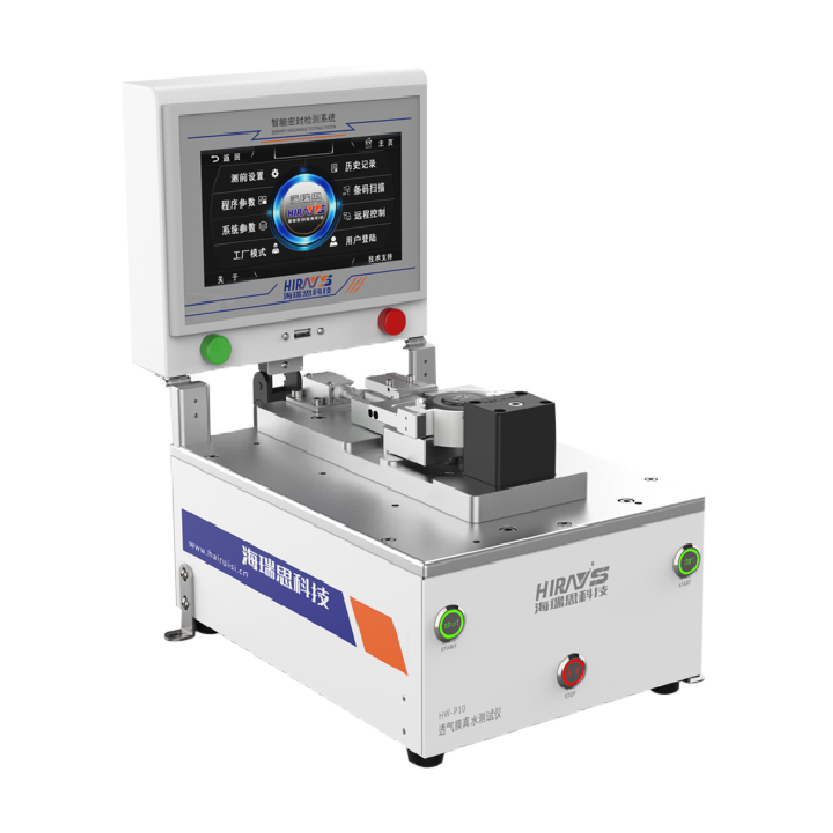

Air Tightness Tester

Uses air pressure or vacuum to test sealing integrity—accurately detects micro-leaks in electronics, connectors, and housings.